![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30RY

Model Number: TP-B30RY

![]() Power: 23.7kw

Power: 23.7kw

![]() Application: Coreless Flat Roll Paper and Core/Coreless Round Roll Paper

Application: Coreless Flat Roll Paper and Core/Coreless Round Roll Paper

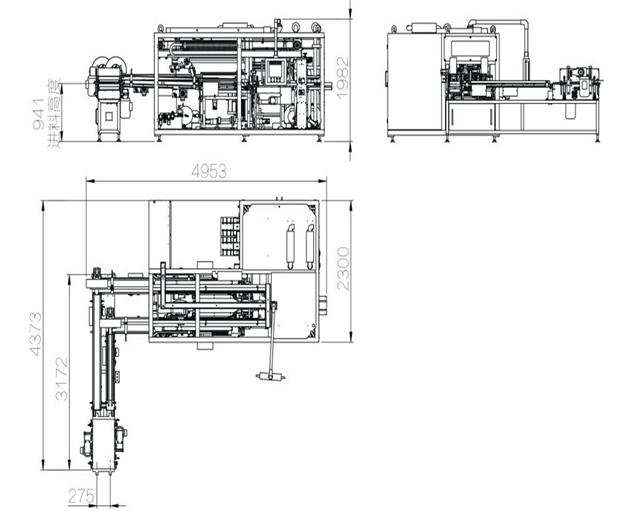

![]() Weight: 3400KG

Weight: 3400KG

![]() Output: 22Bag/min

Output: 22Bag/min

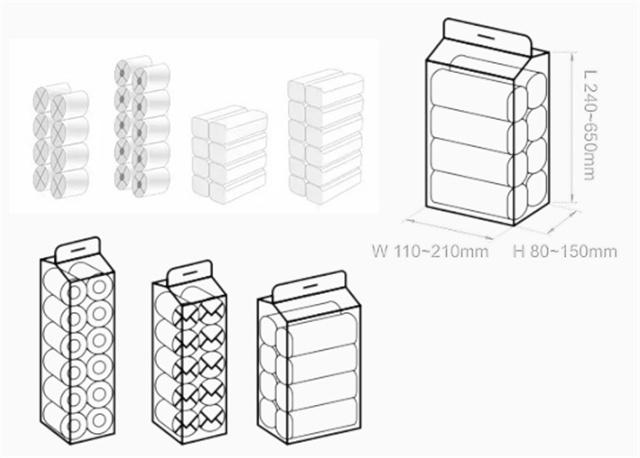

![]() Packaging dimension: Length (L): 240-650 Width (W): 110-210(s type110-420) Height (H): 80-150 mm

Packaging dimension: Length (L): 240-650 Width (W): 110-210(s type110-420) Height (H): 80-150 mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

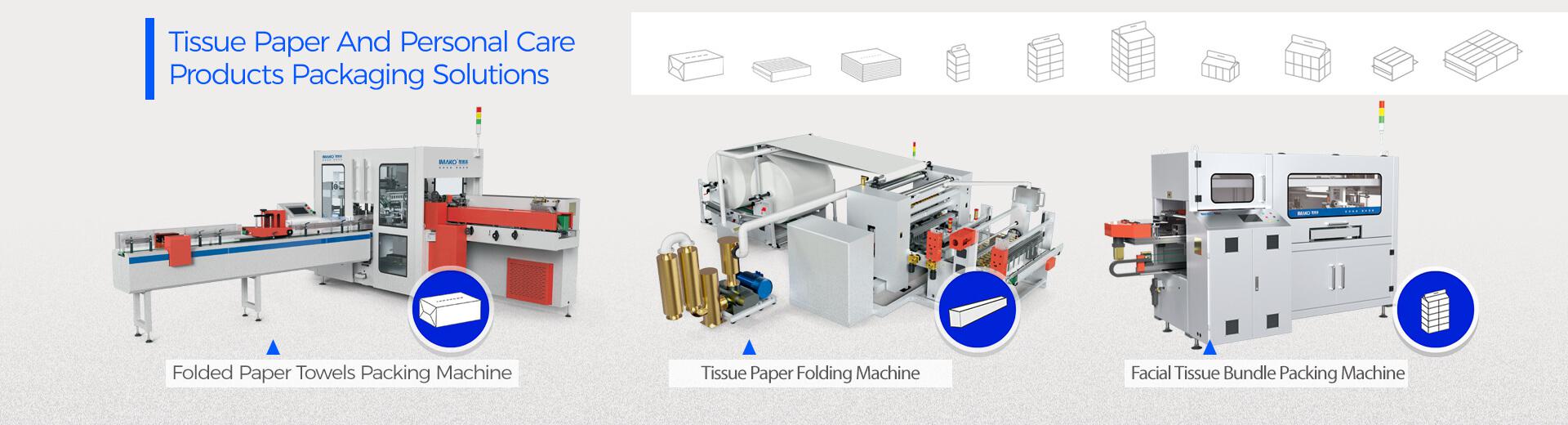

Toilet paper production line refers to the manufacturing process used to produce toilet paper, which is a soft and absorbent paper product primarily used for cleaning after defecation or urination. A toilet paper production line typically consists of several machines that are responsible for different stages of production. In this article, we will discuss the key components of a toilet paper production line and the process involved.

The first stage in a toilet paper production line is pulp making. The raw materials used in the pulp making are primarily wood chips or recycled paper. The pulp making process involves breaking down the raw materials into a slurry using water and chemicals. The slurry is then heated and subjected to pressure to remove excess water, producing high-quality pulp. The pulp is then bleached to produce white, soft, and smooth fibers.

After the pulp making process, the next stage in a toilet paper production line is paper making. In this stage, the pulp is fed through a paper machine where it is flattened into thin sheets. The paper machine consists of several sections, including the headbox, wire section, press section, and dryer section. The headbox is responsible for forming the paper pulp into a continuous sheet, while the wire section helps to remove excess water. The press section reduces the moisture content of the paper, and the dryer section dries out the paper completely.

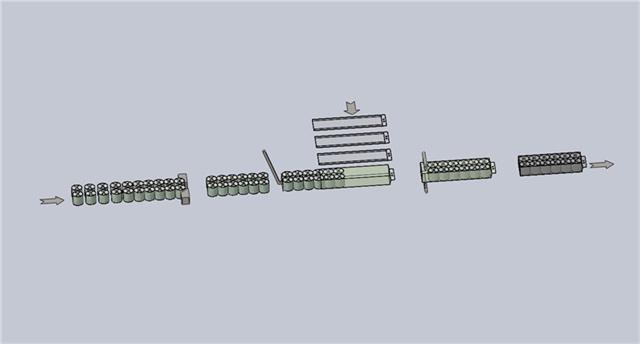

Once the paper is fully dried, it is ready for the final stage, which is converting and packaging. In this stage, the paper is cut into rolls using a slitting machine. The rolls are then transported to the packaging area, where they are wrapped in plastic or other packaging material. The finished products are then packaged in boxes and prepared for shipping to retailers or directly to consumers.

In conclusion, toilet paper production line is a complex manufacturing process that involves several machines and stages. From pulp making to converting and packaging, each stage is critical to producing high-quality toilet paper that meets consumers' needs. Companies that invest in cutting-edge technology and equipment, and employ skilled workers can produce toilet paper of the highest quality while keeping the cost low.

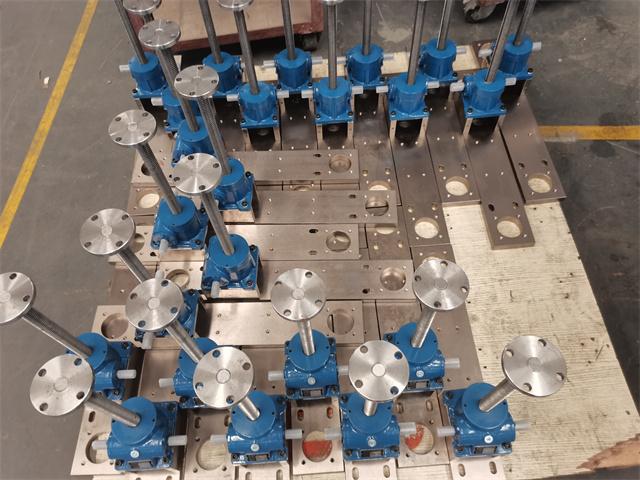

Equipped with functions of bag open protection function, waste bag free stop automatic rejection, air source management, fault alarm and display, servo overload protection.overload protection.

Toilet paper production line refers to the manufacturing process used to produce toilet paper, which is a soft and absorbent paper product primarily used for cleaning after defecation o...

★This machine adopts PLC and 16 shafts servo movement controller for controlling unit, realize servo controlling for product conveying, flatting, counting, bag catch, bag open, tissue ...

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operate and maintain. ★Adop...

Hazel

2024-06-05

Nathan

2024-06-05

lisa

2024-06-05

Camila

2024-06-05

Harper

2024-06-05